Complexity Management – How Packaging Contributes To Supply Chain Challenges & Cost.

Packaging affects every operation throughout the supply chain. It can significantly impact a brand’s sales, operating performance, environmental impact, and cost but can also create significant value. Packaging protects, contains, unitizes, and sells products at the “first-moment-of-truth” on the store shelf. It can provide the consumer with convenience and enables more efficient and cost-effective transportation, warehousing, and picking. Packaging is also an important part of brand-building – a moving billboard for brands whose goods are contained inside each package.

However, there are numerous challenges that the FMCG industry faces when it comes to managing the path to market in an efficient way, including a host of economic, operational, legal, and environmental requirements that need to be fulfilled in an already-complex industry.

Challenges Facing Consumer Brands Businesses Today

Optimized packaging solutions can improve the way a producer fills, stores, and handles packages. Transport providers can benefit from more efficient loading and weight-optimized packaging (i.e. density), while warehouse and store operations want to pick, stack, store and replenish as quickly and easily as possible. This trickles down to the consumers who want to open, use, empty, and dispose of the packaging in a convenient and environmentally friendly manner. It’s easier said than done. Unfortunately, there are several factors that stand in the way of truly efficient supply chain management:

Cost and Sourcing of Raw Materials

Packaging development is a critical element of sustainability and packaging protection. Finding raw materials that go beyond mere protection and meet modern requirements for quality, durability, sustainability, and brand-building at the right cost on a deadline is extremely difficult, particularly considering current market conditions where the supply chain has been constrained.

Supply Chain Disruption

Manufacturers and retailers remain hindered by supply chain disruptions following the COVID-19 pandemic and, more recently, the conflict in Ukraine. Getting a product safely from point A to point B during ongoing volatility has become more challenging. Production runs cannot start until all components are on site, so missing even the smallest, most insignificant item can create significant delays that ripple across the supply chain.

Sustainability

Governments around the world are responding to public concerns regarding the management of packaging waste, particularly single-use packaging. Under-packaging will lead to damage and logistics failures, along with other fees and costs, but over-packaging and excess materials will increase supply chain costs and environmental impact. Brands must embrace an environmentally sustainable model when it comes to packaging design and packaging logistics while minimizing damage and maintaining high levels of customer satisfaction.

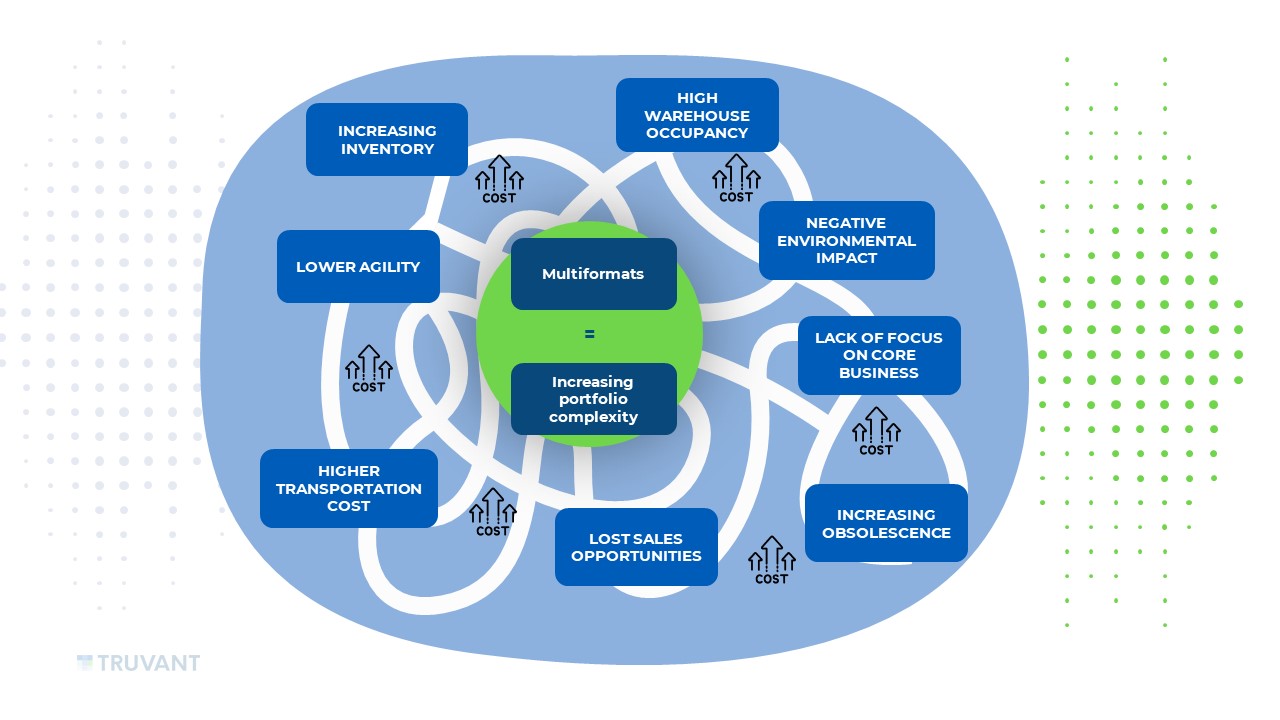

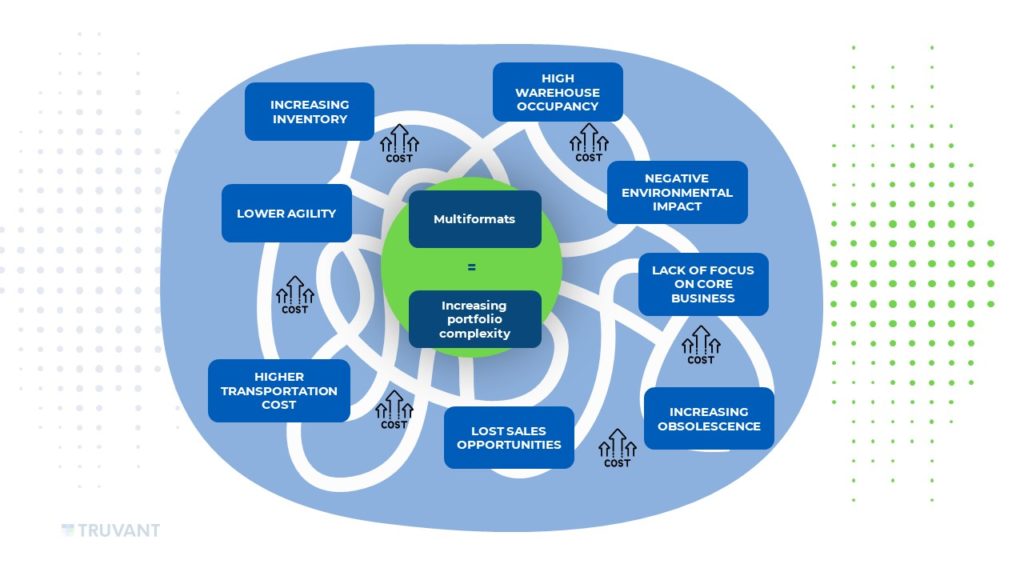

Portfolio Complexity

In order to compete and meet customer demands, brands offer an ever-increasing variety of colors, sizes, combinations, and features to drive growth. This has led to a proliferation of SKUs, which can hamper the ability of manufacturers to accurately forecast demand for each finished good SKU, which can number in the hundreds or even thousands of finished goods. Production efficiency is reduced due to increased line changeovers, while stock-outs are becoming more common, and slow-moving SKUs take up valuable warehouse space and consume precious working capital. Customization such as bundles, gift sets, and store shelf or floor displays add even more complexity and promotional activity with short life cycles that need to be closely managed. It’s very common for consumer products companies to tear down finished goods in the wrong packaging format to be re-packed to meet promotional events or the unique demand of certain events.

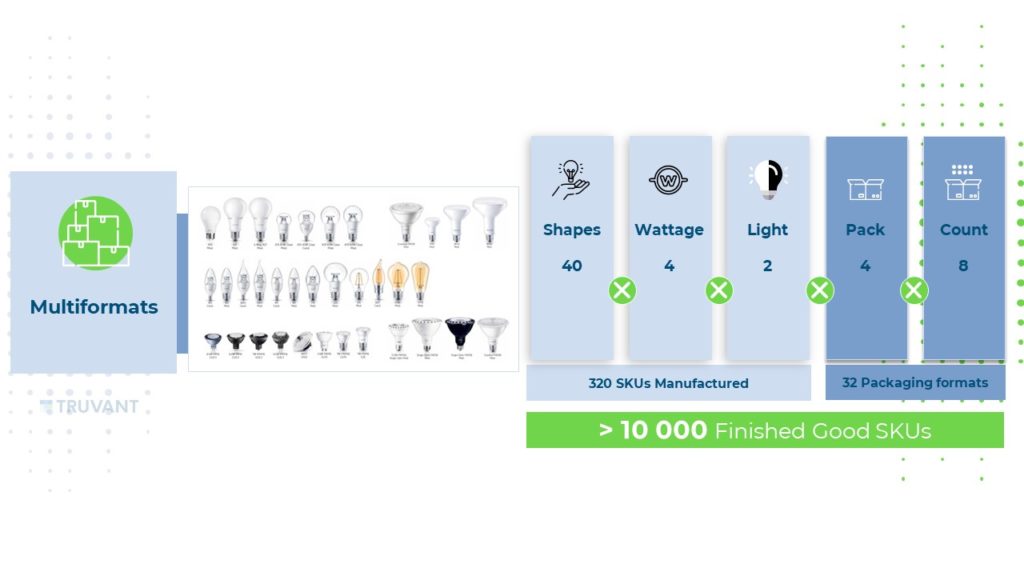

The Impact of Increased Complexity Across the Supply Chain

There is often a trade-off between variety and efficiency in manufacturing.

Let’s take the example of a light bulb company. They sell 40 different shapes of lamps in four different wattages. They may also offer a choice between warm or cold lighting or different color options. Already, these 40 shapes require the manufacture of 320 SKUs (40 x 4 x 2.) This does not just require 320 different packaging formats. There are carton boxes, trays, and blister cards to consider, so the company will require 3-4 different types of packaging. Of course, manufacturers must consider market demand when it comes to packaging count. Retailers may require single packs, two packs, or higher count bundles. If there are eight different types, the number of finished goods will quickly reach and exceed 10,000 SKUS (320 x 4 x 8.) Each of the 10,000 SKUs will require a production plan for packing, shipping, and delivery. How accurate can a forecast be for any one of those finished goods with so many to consider? Demand planning of the base product is much easier and more accurate than trying to guess the mix and formats of finished goods in their final configuration.

Increased Inventory

Minimum order quantities lead to higher inventories of low-sales volume finished pack stock, which can increase transportation, warehousing, and packaging costs. In a world where it’s crucial to minimize costs to maintain a solid competitive advantage, this can have significant negative consequences.

Unnecessary Space

Portfolio expansion and customization can lead to increased inventory levels of finished goods and the multitude of unique components drives the need for ever more storage space. With industrial real estate at a premium and the high cost of operating a distribution network, SKU proliferation and customization activities required to generate lift at retail are creating inefficiencies in the distribution network and requiring more and more storage space to execute.

Lower Agility

When packaging is coupled with manufacturing, smaller volumes lead to smaller runs and increased change-overs, which reduces the agility of the production operation and its line utilization. It may also require additional investment in tooling, and equipment, which drives costs and reduces flexibility. By de-coupling production operations from packaging operations, the complexity can be isolated to a pack center, whose purpose is to be nimble by utilizing a variety of highly flexible packaging lines and efficient run setups. The financial impact of agility can be massive as it can significantly impact a brand owner’s ability to compete in the marketplace.

Lack of Focus on Core Business

Companies often attempt to maximize the value of existing assets by launching multiple product variants with different packaging through as many channels and locations as possible. This can lead to a change in strategy, as they may have previously focused their attention and marketing budgets on promoting a few popular products in larger volume markets. Product packaging needs to be adjusted for each market to enable localization, which impacts the manufacturing processes and business operations. This introduces complexity on a sizeable scale that can force a brand to lose focus on their core mission of designing and marketing great products and getting them to the consumer in the most efficient manner.

Increased Logistics Costs

Carrying more SKUs means dealing with more suppliers and a wider distribution network, which increases packaging requirements and the cost of warehousing, transportation, customer service, administration, and inventory holding. Shipping products in their final configuration is the least efficient from a transportation standpoint and typically results in unnecessary logistics costs and negatively impacts a brand’s environmental footprint.

Lost Sales

Complexity makes it more difficult to accurately forecast, which could lead to running out of stock. Because the time from manufacturing to delivery can take months, the brand loses sales as customers turn to competitors, which over time may impact market share and the value of the brand. Improving packaging processes can lead to lower costs and increased sales.

Increasing Obsolescence

High inventories of low-selling stock can increase the risk of obsolescence due to shelf-life expiry, product discontinuation, or other changes that lead to repacking or product write-offs. Obsolescence has a significantly negative impact on sustainability and a brand’s environmental footprint, as well as operating costs.

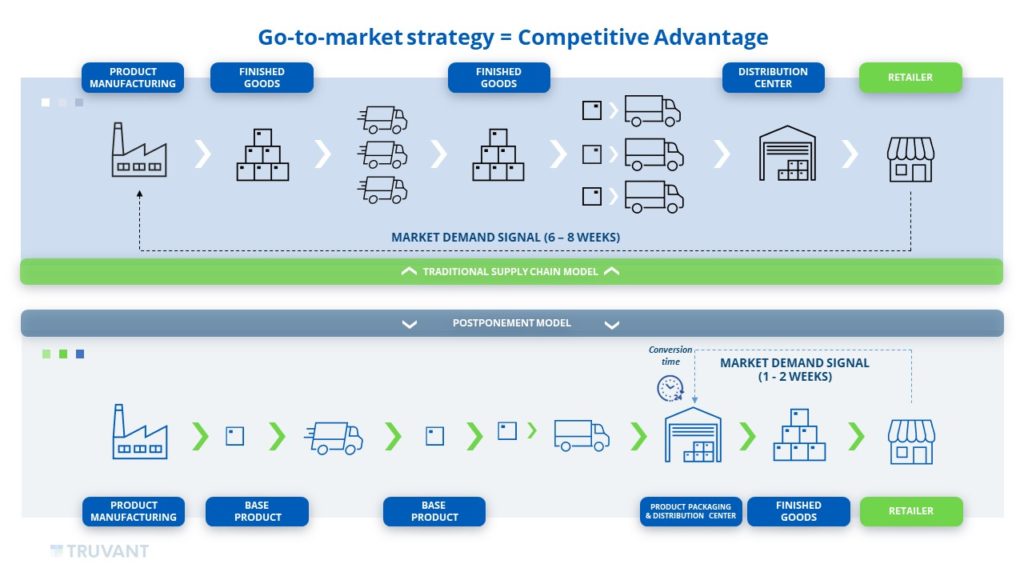

A New Way of Working

There are many ways to deliver a product to a final consumer. Traditionally most companies base their entire supply chain on a final product, and that approach has worked well historically.

As the demand for more packaging formats increases, along with the disruptions caused by the pandemic and other external factors, there’s a real need for a new, improved standard to reduce complexity and optimize the supply chain. Instead of handling, storing, and shipping the product in its final form, brands need to change their approach and adapt supply chains to operate on the base product level – converting it to the finished product at the last possible step when a true demand signal is present (based on actual retail or market orders). Here’s what this approach looks like in practice. Let’s say an oral care brand has 14 base toothbrush products. The products then have variations, including bristle hardness, patterns, head shape, and handle design. This results in 3500 finished goods based on specific requirements, e.g., different pack formats and types, like single and multipacks, bulk packs, shelf-ready packs, and product mixes in a single pack. Then there are regional and localization requirements, including different artwork and languages, private label SKUs, promotional packs, and various customizations. This increases complexity two-hundred-and-fifty-fold and forces manufacturers to make an educated guess of the demand before building an inventory of every SKU variant of the same product.

Fully packaged products require up to 6X the number of pallets to move the same amount of base products which leads to unnecessary warehouse and transportation requirements that result in increased costs and environmental impact. There are even more factors to consider here. Despite their best efforts and most advanced forecasting, a distribution center may still run out of stock of a specific SKU. The manufacturer may need several weeks to replenish the stock and fill the gap on the shelf, which means that customers may choose a competitor’s product instead.It’s clear that the current standards for operation in this example are no longer tenable for this toothbrush brand –and this is a common theme for consumer products companies worldwide.

How Complexity Management Can Tackle These Challenges

Postponed packaging (or late-stage customization) is the practice of keeping a product in a standard format as long as possible. It is only customized according to customer specifications when the demand arises, making packaging more efficient and cost-effective.

Postponed packaging will:

- Reduce transportation costs by moving bulk base products the greatest distance

- Allow customer-specific configuration

- Eliminate rework

- Reduce transportation and warehousing costs

- Reduce the environmental impact with fewer transportation requirements

- Lead to lower overall inventory in the system, higher inventory turns, and reduced working capital requirements

- Facilitate process benefits (demand planning, expedited ordering)

- Improve production efficiency at the base product level

- Reduce the impact of port congestion through densification

- Increase speed to market

- Improve agility and flexibility to help drive growth

Postponed packaging services tackle complexity head-on. By creating a new standard that separates product manufacturing from the packaging process so that it can take place when and where it’s required, it is possible to reduce the burden of complexity for the manufacturer. The manufacturer can achieve higher utilization of their existing resources and focus on their core activities, such as creating innovative products, maximizing the use of current assets, avoiding unnecessary investments, and ultimately improving sales by delivering more “in demand” products to the market more quickly and efficiently.

By moving packaging further downstream in the supply chain, closer to the end consumer and its final destination, companies can deploy capital more efficiently and maximize productivity.

Conclusion

A postponed packaging process creates value upstream and downstream throughout the entire supply chain. Companies will enjoy improved manufacturing efficiency and capital utilization and lower transportation (via density) and warehousing costs (via more inventory turns), which leads to a lower cost of goods sold – and plays a crucial role in protecting the environment.

If you would like to know more, get in touch with Truvant. Our Pack Centers have successfully followed a packaging postponement model for more than 15 years. We focus on striking the right balance between complexity and inventory reduction and high flexibility adjusted to actual demand. We’ve managed to maximize the efficiency of the entire packaging process, leading to high responsiveness and speed to market. This means that brand owners will never miss an opportunity to get the right product, in the right packaging, to the right place, at the right time.

Advent Calendar Seasons: Truvant’s Expertise in Creation and Packaging Advent calendars are a beloved holiday tradition that can be enjoyed by people of all ages. They are a fun and festive way to count down the days to Christmas. Advent calendars are typically filled with small treats, such as chocolates, candies, or toys. However, […]

The External Business Partner Excellence Award was created by P&G to honor the contributions of those suppliers that have “gone above and beyond in delivering value” to the business. Truvant is the largest pure-play packaging services provider in the world, delivering manufacturing, packaging, and display solutions to the world’s leading brands. The company delivers high-quality, […]

Company Announces Appointment of Colleen Soukup. Truvant, a leading global packaging services company, today announced that Colleen Soukup has been elected to the company’s Board of Directors. Mrs. Soukup recently retired from General Mills, Inc after a 39-year career with the Minnesota-based multi-national food company. Her last position upon retirement was Chief Procurement Officer. […]