REDUCING WASTE. INCREASING ECO-FRIENDLINESS.

Since 1994, we have worked closely with many of the world’s top food, household, and industrial brands

We work tirelessly to provide our partners with the best locations, processes, automation, package design, and materials suppliers for their products.

With one of the most advanced production facilities in the industry, we offer manufacturing solutions for food and liquid products along with a wide range of primary and secondary packaging, e-commerce packaging, and order fulfilment services. All of this is achieved alongside an increased focus on ecological friendliness.

REDUCING WASTE AND CARBON FOOTPRINT – INCREASING ECO-FRIENDLINESS.

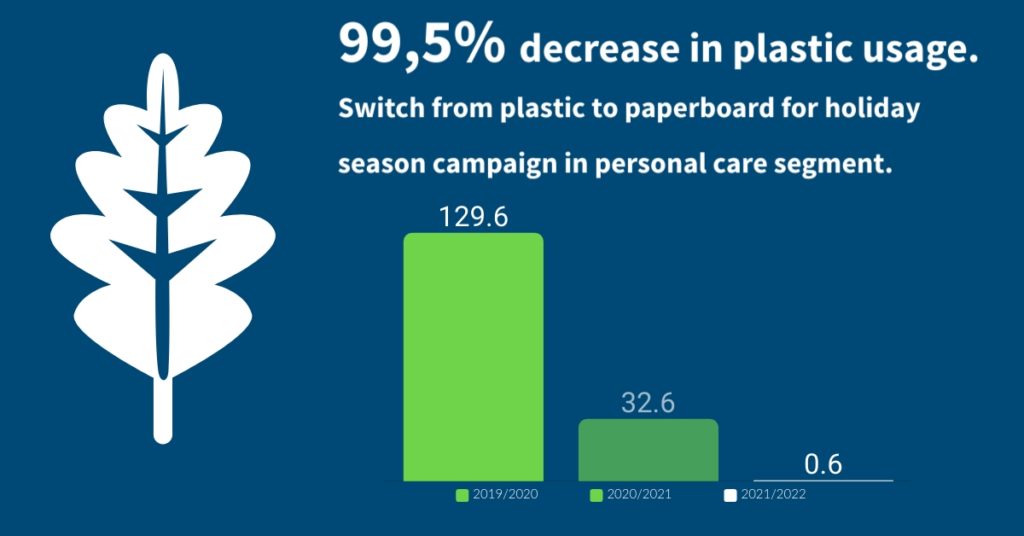

Our commitment to plastic consumption reduction is apparent in our holiday campaign for a leading personal care products company. For the 2019/2020 holiday season, plastic consumption was measured at 129.55t but by the holiday season 2020/2021, this was reduced to 32.6t — and, finally, in 2021/2022, it was just 0.6t. This outstanding reduction was achieved by working closely with our customer to transition from plastic to paper components across the portfolio. For the 2020/2021 campaign, a mix was used — part of the portfolio had paper inserts made of corrugated while others were plastic. For the 2021/2022 campaign, all inserts were made of paperboard. The plan for 2022/2023 is to simplify the paper inserts to further reduce material consumption.

This outstanding reduction was achieved by working closely with our customer to transition from plastic to paper components across the portfolio.

Another example of our successful reduction of plastic consumption is the seasonal campaign executed by Truvant for a global male grooming products brand. For the 2019/2020 campaign, 79.5t of plastic inserts were used, while in the 2020/2021 and 2021/2022 campaign, usage was limited to just 0.72t. In 2019/2020, plastic inserts were used, while in the following year, there was a change to pulp inserts made with 100% PIR. In 2021/2022, inserts made of corrugated were used instead.

The plan for 2022/2023 is to eliminate the inserts completely and fill the empty spaces in the package with tissue paper or reduce the use of paperboard by downsizing the packages and simplifying the inserts. Paper consumption in the 2021/2022 campaign amounted to 352t, while for the 2022/2023 campaign the estimation is 175t, which means a significant reduction of approximately 50%.

For one of the world’s biggest high-quality battery brands, Truvant is working to reduce the thickness of the blister foil by 20-33% in 2022, which results in a realistic reduction of plastic by approximately 30% for this part of the brand’s portfolio. In 2020, the total consumption of plastic for these structures summed up to 117.5 tons.

A similar approach was taken by another innovative battery brand. In this case, the plan is to almost eliminate plastic entirely from the entire portfolio. The implementation of improved packaging is planned for later this year, while most of the development work took place in 2021.

Again in 2021, Truvant worked closely with a leading global consumer products company to reduce their carbon footprint by physically moving their packaging operations closer to end markets, resulting in a major reduction in the amount of air and ground transportation required to get products to the consumer. This was achieved by shipping base products in densely packed bulk containers from the customer’s manufacturing facilities to Truvant facilities that were located closer to the consumer. By shipping products long distances in bulk formats, the customer was able to eliminate hundreds of air shipments and thousands of sea and ground shipments which had a major impact on Co2 emissions. All of this significantly reduced transportation costs and brought the product to market faster with more flexibility to respond to changes in demand.

This takes innovative thinking, reliable processes, and market-ready designs that significantly reduce the environmental impact of packaging.

IMPROVING INNOVATION. OPTIMIZING OPPORTUNITIES.

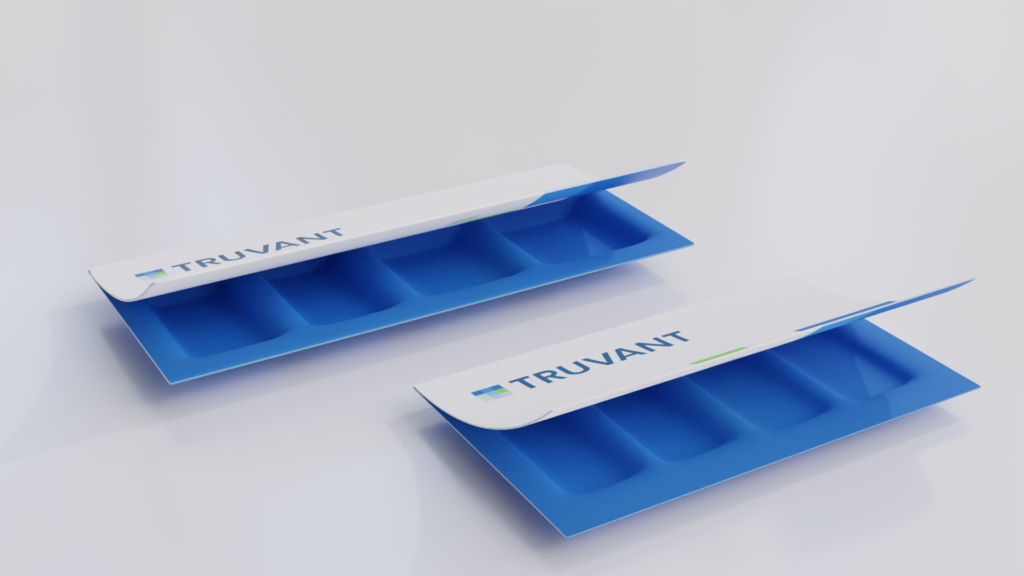

In order to further increase a market outreach of environmentally friendly packaging, Truvant offers brand owners innovative, reliable, market-ready solutions that allow our customers to quickly transition from plastic to sustainable paper-based packaging. We are responsive to the needs of our customers and to support them, we will install a new, sophisticated Syntegon TPU 1000 form, fill, and seal packaging line that utilizes 100% paper-based materials at Truvants world-class production facility in Stryków, Poland.

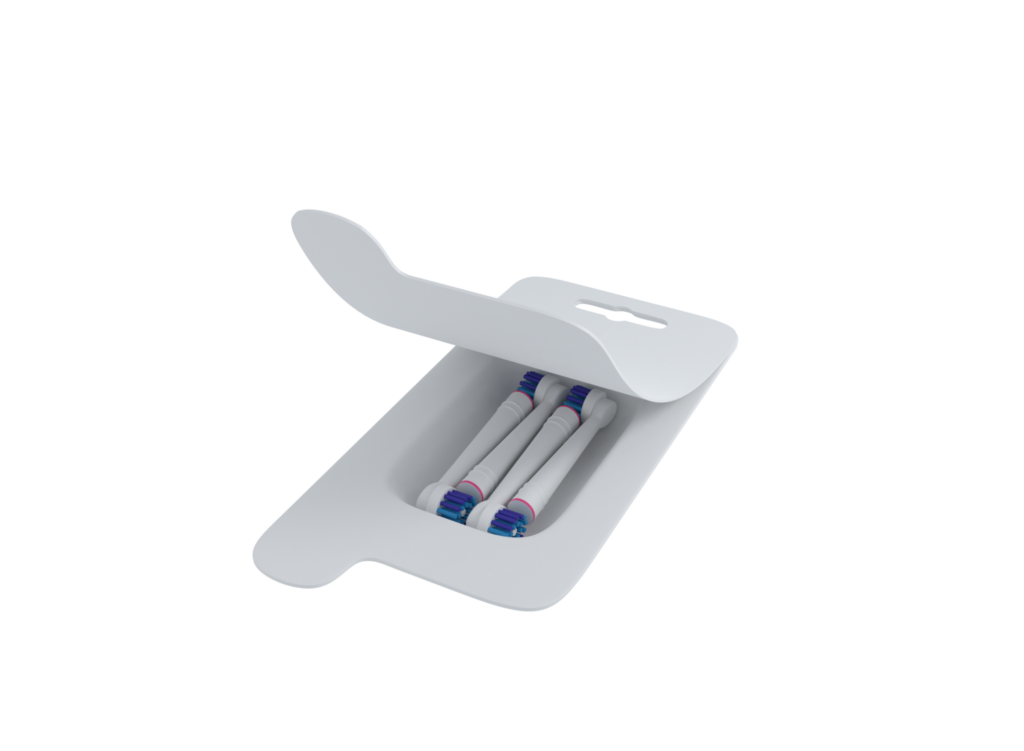

This highly automated packaging line processes particularly stretchable and moldable paper, allowing for up to ten times deeper embossing than regular paper and providing a multitude of sustainable alternatives to traditional plastic packaging. The TPU 1000 material allows us to create unique 3D blisters, trays, or pods using fully recyclable materials. This state-of-the-art technology significantly reduces both waste and the ecological footprint associated with product packaging.

Truvant creates scalable, end-to-end solutions for each of our customers and focuses on optimizing the process of getting our customer’s products to market. We start by designing the initial packaging and choosing the right materials and then manufacturing and delivering the finished product. Our customers can expect shorter time-to-market and increased efficiency with reduced complexity and reliable sustainability that meets their objectives.

We are committed to providing consumer brands with reliable and innovative packaging with minimized ecological impact. Our primary goal is simple: give brands the ability to test, implement, and bring sustainable packaging concepts to market — quickly and efficiently.

It is worth mentioning that the German Packaging Institute (Deutsches Verpackungsinstitut e.V.) has honoured the revolutionary TPU 1000 with the German Packaging Award for sustainability. With its versatile paper forming capabilities, this sophisticated technology offers an outstanding alternative to plastic, which is a great way to enhance the sustainability of brands’ products.

MAKING THE SWITCH TO RECYCLED MATERIALS

A big part of becoming a sustainable manufacturer is switching to recycled materials, both in the product itself and the packaging it is shipped and sold in. Together with our partners, Truvant has achieved significant improvements in packaging processes, noticeably reducing the number of materials used and switching to recycled ones. Some examples of our collaborative efforts include:

- Personal Care Products Brand: Switching from 100% virgin material to 95% total recycled content (60% of which is PCR).

- Male Grooming Products Brand: Transitioning from 100% virgin material to 80% total recycled content (50% PCR).

- High-quality batteries brand transitioned over 95% of materials utilized from virgin raw material to recycled materials.

A TRULY SUSTAINABLE PACKAGING SUPPLIER

These inspiring partnerships with global brands show that sustainable packaging is the future. Together we are able to provide state-of-the-art solutions using innovative thinking about the supply chain and sustainable materials that significantly reduce the environmental impact of packaging.

“We have been providing our customer’s solutions that aim to decrease their costs, transportation and materials usage — all while supporting sustainable packaging for their products,” said Maja Urban, Truvant Sustainability Manager. ”

We are also aware of the importance of ESG topics, and as a responsible and reliable partner for our customers, we have been working toward their further development and proper communication. We are currently producing our first sustainability report for Truvant that we will publish this year.”

At Truvant we are committed to minimizing the ecological impact on our business partners. We achieve this goal through innovative and sustainable packaging, sophisticated technology, supply chain thought leadership and expert knowledge. From packaging design to the selection of materials to the delivery of the finished product, all these efforts allow us to create end-to-end solutions that address the many complex challenges our customers face every day.

As the United States has implemented tariffs across the globe, brands and consumers are feeling the pressure. Rising costs for packaging materials, shipping disruptions, and an unpredictable trade environment have forced many brands to rethink their supply chains. CPG brands are looking for more than a co-packer – they’re looking for a strategic supply chain […]

Advent Calendar Seasons: Truvant’s Expertise in Creation and Packaging Advent calendars are a beloved holiday tradition that can be enjoyed by people of all ages. They are a fun and festive way to count down the days to Christmas. Advent calendars are typically filled with small treats, such as chocolates, candies, or toys. However, […]

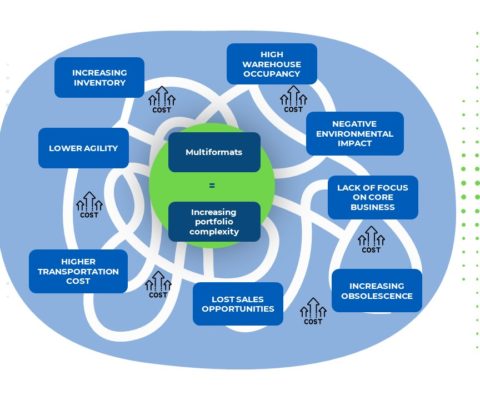

Packaging affects every operation throughout the supply chain. It can significantly impact a brand’s sales, operating performance, environmental impact, and cost but can also create significant value. Packaging protects, contains, unitizes, and sells products at the “first-moment-of-truth” on the store shelf. It can provide the consumer with convenience and enables more efficient and cost-effective transportation, […]